New customers save 5% with the code GET05

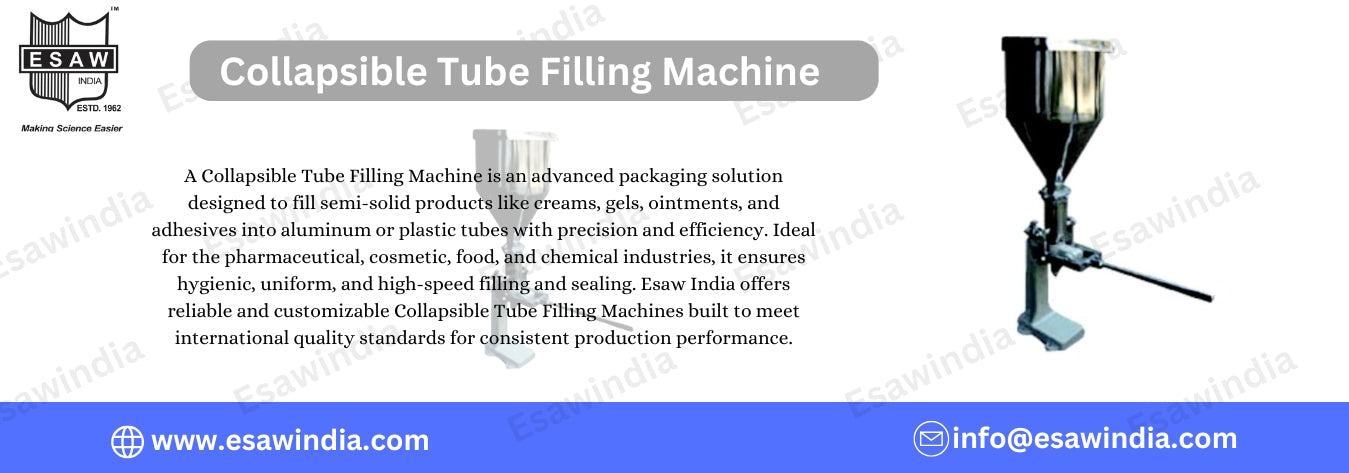

Collapsible Tube Filling Machine by Esaw India

In today’s competitive manufacturing landscape, efficiency, hygiene, and precision are the cornerstones of success—especially in the packaging industry. One of the most critical machines in this sector is the Collapsible Tube Filling Machine, a piece of equipment that revolutionizes the way products are packaged, ensuring consistency, speed, and reliability.

From cosmetics and pharmaceuticals to adhesives and food products, collapsible tube packaging is essential for easy storage and controlled dispensing. A trusted name in industrial and laboratory machinery, Esaw India stands at the forefront of innovation by delivering top-quality Collapsible Tube Filling Machine systems tailored to meet diverse industry requirements.

What is a Collapsible Tube Filling Machine?

A Collapsible Tube Filling Machine is a sophisticated piece of equipment used for filling semi-solid materials like ointments, creams, gels, and pastes into aluminum or plastic tubes. The machine automates the filling and sealing process, improving product safety, minimizing contamination, and maintaining uniformity.

These machines are invaluable in industries where hygiene, precision, and speed are vital—such as in pharmaceuticals, cosmetics, toothpaste production, and chemical industries. As one of the leading manufacturers in the country, Esaw India designs machines that combine cutting-edge technology with durable engineering to meet modern packaging demands.

Key Features of a High-Quality Collapsible Tube Filling Machine

1. Automated Filling Mechanism

Modern machines automatically fill a pre-set volume into each tube with great accuracy, eliminating human error and ensuring consistent product quantity.

2. Sealing Efficiency

Whether dealing with aluminum, laminate, or plastic tubes, sealing is crucial. A good machine can heat seal, crimp, or fold the tube end perfectly depending on the material.

3. User-Friendly Interface

Top-tier models, such as those from Esaw India, come equipped with intuitive control panels or touchscreen PLC interfaces that allow easy setup, real-time monitoring, and troubleshooting.

4. High-Speed Output

Machines are designed for high-volume production lines, capable of filling anywhere from 30 to 120 tubes per minute, depending on the model and product.

5. Hygienic Design

In sectors like pharmaceuticals or cosmetics, sanitation is critical. Machines are made with stainless steel parts that conform to GMP standards.

Why Esaw India is a Trusted Name in Tube Filling Machines

With decades of experience and a strong commitment to engineering excellence, Esaw India has become synonymous with quality in laboratory and industrial automation. Their Collapsible Tube Filling Machine range is highly regarded for reliability, ease of use, and customization.

What Sets Esaw India Apart:

-

Customizable Configurations: Tailored to your tube sizes and filling capacities.

-

Durable Build Quality: Stainless steel construction for long-term use.

-

After-Sales Service: Nationwide service network for installation, training, and support.

-

Affordable Pricing: Competitive without compromising quality.

-

Versatility: Machines can fill a range of products from pharmaceuticals to cosmetic creams.

When you invest in a Collapsible Tube Filling Machine from Esaw India, you’re not just purchasing a product—you’re gaining a long-term partner in your manufacturing journey.

Applications Across Industries

1. Pharmaceuticals

Used for filling medicinal creams, gels, antiseptic pastes, and ointments. These machines must comply with strict hygiene and dosage regulations.

2. Cosmetics

Ideal for products like lotions, face creams, sunscreens, and shampoos. The aesthetic aspect of packaging is also a priority in this sector.

3. Food Industry

Filling condiments like mustard, mayonnaise, sauces, and purees into collapsible tubes for single-use or travel-sized packaging.

4. Adhesives and Chemicals

In the industrial sector, these machines are used to fill glues, lubricants, and other pastes into tubes.

By using an advanced Collapsible Tube Filling Machine, companies across these sectors can boost their productivity and ensure consistent product quality.

Advantages of Using a Collapsible Tube Filling Machine

1. Speed and Efficiency

Manual filling processes are slow and prone to inconsistencies. A machine significantly increases output with precise accuracy.

2. Consistency

No more worries about overfilling or underfilling. Every tube is filled to the exact specified volume.

3. Labor Cost Reduction

Automating the filling and sealing process reduces dependence on manual labor, saving long-term operational costs.

4. Reduced Waste

Minimized spillage and precise dosage ensure optimal use of raw materials.

5. Improved Hygiene

With enclosed systems and stainless-steel bodies, contamination is significantly reduced—especially important in pharma and cosmetics.

This is why leading manufacturers across India and abroad turn to Esaw India for reliable Collapsible Tube Filling Machine solutions.

Choosing the Right Tube Filling Machine

Before making an investment, it's important to assess your production needs:

a. Tube Type & Size

Ensure the machine can handle the material (aluminum, plastic, laminate) and dimensions of the tubes you use.

b. Product Viscosity

High-viscosity products (like creams or adhesives) need machines with specific pressure control and heating capabilities.

c. Production Volume

Choose a model based on your daily or hourly output requirements. Esaw India offers models for both small-scale and large-scale operations.

d. Cleaning & Maintenance

Easy disassembly and cleaning features are essential, especially in multi-product environments.

e. Power & Space Requirements

Make sure your facility meets the electrical and space specifications for installation.

When you're uncertain, the experts at Esaw India are just a consultation away to help recommend the perfect Collapsible Tube Filling Machine for your operation.

Maintenance Tips for Optimal Machine Performance

-

Regular Cleaning: Prevent residue buildup that may clog nozzles.

-

Lubrication: Keep mechanical parts well-oiled for smooth performance.

-

Check Seals: Inspect sealing mechanisms for wear and tear.

-

Software Updates: If applicable, ensure digital interfaces are running the latest version.

-

Operator Training: Properly trained personnel ensure safer and more efficient use of the machine.

Routine maintenance not only prolongs the life of your Collapsible Tube Filling Machine but also keeps production running smoothly.

Final Thoughts: Why You Should Invest Now

Whether you're a startup entering the cosmetic industry or a large-scale pharmaceutical producer looking to scale operations, investing in a high-quality Collapsible Tube Filling Machine is a strategic decision that can transform your packaging workflow.

The advantages are clear—enhanced efficiency, product consistency, hygiene control, and cost savings. And with Esaw India, you gain a partner who brings expertise, innovation, and service excellence to the table.

If you're looking for performance, precision, and peace of mind, make your next move with Esaw India's Collapsible Tube Filling Machine.

Leave a comment